The world’s first ship to transport liquefied hydrogen left Japan on Dec. 26 to fetch its first cargo from Australia in a landmark moment for the global hydrogen industry.

The tanker, built by Kawasaki Heavy Industries, is expected to return with its cargo in late February after making the 18,000 km round trip. The project is the result of a $362 million (£268 million) collaboration between the Japanese and Australian governments and kicks off a market that is expected to eventually surpass the $50 billion transport of liquefied natural gas (LNG).

Kawasaki Heavy is looking to replicate its success in the LNG tanker market, which transports some 360 million tonnes of LNG via the world’s oceans every year.

Creating a global market for hydrogen will enable low-cost producers to export excess output to countries where it is either difficult to produce the required volumes or too expensive.

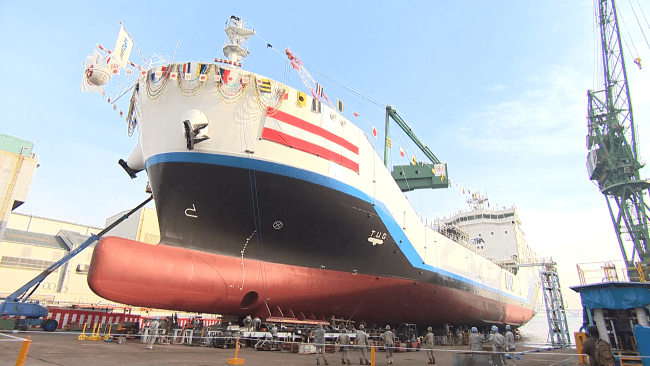

The Suiso Frontier, the world’s first liquefied hydrogen carrier, has launched.

In October 2021, Ryze Hydrogen along with JCB signed a deal to take 10% of the green hydrogen produced by Australian firm Fortescue Future Industries and then distribute it in the UK. Plans for the hydrogen to also power the ships that carry it are developing.

Countries with low renewable energy costs, such as Namibia, or an abundance of natural gas, such as Saudi Arabia (which also has the world’s lowest solar costs), are betting on the economics of producing green and blue hydrogen at competitive prices and shipping it around the world.

However, the industry is still at a very early stage. Shipping liquid hydrogen is even more complicated than LNG because of the temperatures it needs to be stored at to keep it liquid – minus 253 degrees Celsius, just 20 degrees above absolute zero (the coldest possible temperature). That’s 100 degrees lower than LNG.

Kawasaki is planning on building a commercial-scale hydrogen carrier by the mid-2020s with the aim of snagging its first paying customers by 2030.

A hydrogen tanker is also being built by Korea Shipbuilding & Offshore Engineering, which has been working with a steelmaker to develop high-strength steel and new welding technologies to handle the super-cold temperatures.

In Norway, Wihelmsen Group is building a roll-on/roll-off ship that will be able to transport liquid hydrogen in containers that are driven onboard and expects it to be operational by 2024.

Canada’s Ballard Power Systems and Australia’s Global Energy Ventures are taking a different approach with the development of a ship to transport compressed hydrogen in gas form by 2026. While such a system does not require any extreme temperatures, less cargo can be moved at a time. A 40-foot container could carry about 800-1,000 kg of pressurized hydrogen gas, but up to 3,000 kg of liquid hydrogen.

Click here to learn more about Ryze Hydrogen.